|

Galileo Controller

- the most advanced and reliable irrigation & climate control

equipment in the market!

Galileo

is a computerized agricultural control system, among the most advanced

in its field, for climate control and irrigation in green houses and

irrigation control of large open fields, farms, orchards, turf, public

gardens and more.

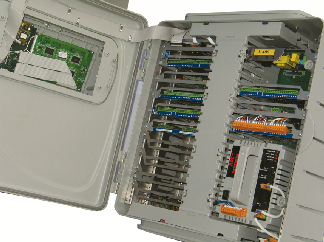

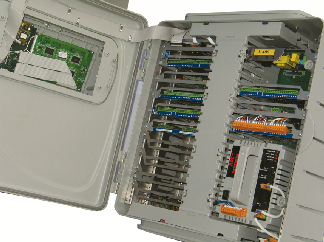

The Galileo W models include input/outputs slots in which the I/O cards

can be fitted.

The available Galileo W models are:

Galileo W

a modular controller in the advanced "small casing"(4 slots).

Galileo WEX

a modular controller in the advanced "large casing"(4 I/O slots and 4

protection slots).

Galileo WEXX

a modular controller in the advanced "large casing"(8 I/O slots, 4

protection slots,

L-485 slot). For full protection a small casing is added.

AC Models

All of the models include:

• Power Supply - 24 VAC

• Output Voltages - 24 VAC

• Discrete Inputs - On/Off

• Analog Inputs - 4-20 mA

AC I/O Cards

Each I/O cards can be fitted in any of the controller's slots.

• 8 Inputs/16 outputs - serves as a basic unit (is included in the price

of the controller)

• 24 Outputs

• 16 Analogs

• Wire RTU Adapter - see more in the following RTU chapter

• One way Radio RTU adapter

• Two way Radio RTU adapter

DC Models

• Power Supply: 12 VDC

• Consumption: 150 mA approx.(when the display is switched off)

• Outputs: 12 VDC latching

• Discrete Inputs : On/Off

• Analog inputs: 4-20 mA

DC I/O Cards

• 8 inputs/8 outputs

• 16 analogs

• Wire RTU Adapter

• One way RTU Adapter

• Two Way RTU Adapter

Remote Terminal Units (RTU)

These are small units with several inputs and outputs, installed in the

field at a distance of a few km from the controller. The unit is

connected locally to the elements (solenoids, meters, sensors etc.), it

is constantly in communication with the controller receiving operational

command and transferring data back to the controller.

There are 3 types of RTU:

The system consists of a CRTU adapter inserted into the controller, a 3

wire single cable that can be up to 6 km long along which the CRTU units

are installed.

A combination of units with a total of up to 128 outputs can be

installed along the cable. Two such cables can be installed on one

controller.

There are two basic CRTU models

Cable RTU (CRTU)

The system consists of a CRTU adapter inserted into the controller, a 3

wire single cable that can be up to 6 km long along which the CRTU units

are installed. A combination of units with a total of up to 128 outputs

can be installed along the cable. Two such cables can be installed on

one controller.

• CRTU-2: 2 Outputs - 12 VDC latching; 4 Inputs (On/Off)

• CRTU-4: 4 Outputs - 12 VDC latching, 8 Inputs (On/Off),

4 Analogs - 4-20 mA or 0-10 V

Radio RTU AP (1 way RRTU)

This system transmits a radio signal from the controller to a distance

of up to 5 km (depending on the field conditions), the signal is

received by the radio RTU and can open or close outputs. (This unit does

not include inputs).

The system consists of:

• Serial Transmitter (SRT): includes: 1W-RRTU adapter (located inside

the controller), data cable, radio transceiver and an antenna.

• Field Units: includes:

• 2 or 4 12 VDC latching outputs

• A lithium battery, 3.6 VDC which lasts under field conditions up to

2-3 years.

• The unit is enclosed in 100% water proof, epoxy molded housing.

• Each unit is loaded with its own "private" code number using a

portable terminal.

Radio-Gal (2 way RRTU)

The controller is connected via radio to units that consist of outputs,

inputs and analogs. The controller scans the units in the field via

radio, transmitting the command to open or close outputs and receiving

the data from the inputs and analogs. During each scan cycle the

controller receives the number of pulses entered and the time (in

milliseconds) between the last two pulses thus assuring that pulses

can't be lost in the air. The system consists of:

• Transmitting Unit: That includes an interface card inside the

controller a radio transceiver and an antenna.

• Field Units: Each unit includes:

• Small transceiver

• Batteries: 2-8 x D size lithium 3.6V

• I/O: 4x outputs (2 or 3 wires), 2 input, 2 analogs

• Coding: by dip switch

Keyboard and Display Console

Identical in all Galileo models, consists of a wide 25 rows LCD display

and a 24 keys keyboard used for programming and data presentation. All

types of programming can be performed by the console.

The console can be installed in 3 positions in the controller casing (on

the front door or on the top or bottom of the casing).

Memory Backup

The RAM is backed up by a lithium battery, installed on the main board

that lasts for at least 5 years thus assuring that data is not lost even

in the event of power failure.

Communication Ports

• One RS-232 port output for communication with a remote PC.

• One RS-485 port for connection to an expansion unit or ECpH monitor.

Galileo - Central PC Computer

The advantages of connecting the controllers to a PC are:

• Remote Control:

Instead of working out in the field it is possible to carry out the same

tasks from the comforts of your air conditioned office.

• Central Command:

Several Galileos can be connected to one computer, allowing the control

of a very large area from a single location.

• Graphical Presentation:

It is possible to see an on-line presentation of the field showing all

active elements and the system status in an understandable, familiar

way.

• Data Acquisition:

The computer can collect a variety of types of data such as Valve

Accumulations, Water Meters, Water Meter Flow Rates, Irrigation

Information and more.

Many types of reports and graphs can be shown. The reports can be set

for ranges varying from a single hour up to a full year. Some of the

reports are highly specialized, for example a report of fertilizer

elements (nitrogen, phosphorus, potassium etc.) per valve.

The data can be exported to an Excel data sheet for further analysis.

Communication with the central computer:

• Direct connection - by cable up to 20 meters.

• Long distance cable by a special cable modem (L485), up to 4 Km

enabling controller networks.

• Cellular modem (including GPRS).

• Radio communication - range of up to 20 km. Extra range can be

achieved via repeaters.

Galileo - Software Description

Several types of software (applications) can run on the same previously

described hardware. The different application is selected according to

the type of project.

The available applications are:

• Open Field irrigation

• Green Houses

• Irrigation

• Climate

• Nursery irrigation

The Open Field Irrigation Application

This unique application is designed to provide a solution for a wide

variety of irrigation needs. It can be used in very small irrigation

systems such as a home garden or for the largest systems such as

irrigation communities. The system fully supports the use of cable and

radio RTU. The Open Field PC Software is graphic and allows the user to

draw a realistic picture of the field.

Setup Features

Pipe Lines & Main Valve (up to 70)

In this unique system each pipeline can be connected to another pipeline

thus enabling defining the pipelines as a network.

The pipelines can be set in the same way as they appear in the field.

This enables:

• Hierarchy

of main valves and head definition.

• Gradual

opening and closing of irrigation to prevent high pressure buildup.

• Flow rate

limit to a pipeline (in the case of bottle necks). Upon programming the

limiting flow rate, the system does not allow the actual flow rate to

exceed the limit by detaining irrigation programs when the flow rate is

already too high.

• Protection

of definition errors such as fertilizer pump not in route to the valve

using it.

Irrigation Valves (up to 200)

The valve features include accumulation data of water, time and up to 7

different fertilizers.

Water Meters (up to 100)

The water meters characteristics include the ability to divide the

amount and flow rate of water measured by the water meter between the

valves using it (according to the valves' nominal flow rates). It allows

using one water meter for many valves, whilst operating and accumulating

each valve separately.

Fertilizer System: there are two fertilizing elements

Local fertilizer pump (up to 30) using a simple operation program

(included in the irrigation program) and Fertilizer Center (up to 10)

that includes the operation of up to 6 fertilizer pumps, control of EC

and pH and more.

Pump Houses (up to 5)

A special program to control the operation of a combination of up to 5

water pumps.

Virtual Water Meters (up to 20)

An element that consists of up to 20 water meters. It shows the sum of

the flow rate and the accumulation of water meters. The virtual water

meter can also show the balance of the flow rate at a certain point

allowing the use of the element called Burst Control (Net Protection).

Pause Element (up to 10)

An element which contains a condition input and/or a sensor (such as

pressure transducer) and can pause the pipe line it is connected to, as

a condition of the input/sensor status.

Mixing Junction (up to 5)

A program that controls the dilution of water such as drainage water

with fresh water, according to the EC of the resulting mixture.

Irrigation programs (up to 200)

Each irrigation program includes:

• Up to 50 valves for operation

• Quantity or duration

• Local Fert. Pump

• Selection of Fert. Program of fertilizer center

• Over/under flow alarms

• Sequential operation

• Start and stop time

• Cyclic irrigation

• Daily (days of the week)

• Conditioned irrigation

• Many other options

The Green House Application

This application combines an irrigation system and up to 4 climate

control systems in the same controller.

Green House Irrigation System

The system is composed of one irrigation head in which a fertilizer

center performs sophisticated fertilizer injection of up to 8 different

fertilizers whilst carrying out the essential control of conductivity

and acidity of the irrigation water.

Galcon produces three type of machines suited to this application:

Green House Irrigation Capabilities

The following elements can be operated by the irrigation system:

• One irrigation head including: main valve, water pump, main fert, etc.

• Up to 100 valves

• Up to 8 fertilizer pumps

• Up to 5 fert. selectors

• Up to 10 filters

• Up to 20 drainage sampling outputs

• Up to 40 misting valves

• Additional elements

The following elements can be read by the irrigation system

• One water meter

• 8 fertilizer meters

• Up to 100 sensors

• Special mixer Inputs

• Special mixing and recycling inputs.

Programming Features:

• Up to 100 irrigation program can be set, each containing:

• Up to 4 valves directly and 16 valves. indirectly worked by a single

program.

• Preset fertilizer programs: Up to 50 different fertilizer programs in

which the proportion of fertilizer/water for each fertilizer pump is set

along with the EC/pH requirement.

• The time range for operation.

• Up to 5 hourly start times per day.

• Cyclic irrigation.

• Several options of manual overriding.

• Misting programs:

Up to 40 foggers with a fogging program each containing:

• Time of operation.

• Time of cycle that can be altered by the conditions of temperature,

humidity and other conditions.

• The use of logical conditions for operation.

• Sequential operation.

• Drainage Sampling: Up to 20 sampling points can be connected to the

controller via a device called "Dagan". It measures the quantity, EC and

pH automatically and corrects the next irrigation properties

• Filter Flushing: Up to 10 filters divided between up to 2 stations can

be programmed.

Green house Climate Control

The system includes a large diversified and flexible software package

that can be fitted to the use of almost any farmer without any special

modifications.

Climate System Sensors

• Internal Sensors

in the greenhouse includes: temperature, humidity, CO2 and more.

•

External Sensors

includes: wind velocity and direction, radiation, rain meter, external

temperature and humidity and more.

• The normal temperature, humidity and radiation are carried out by a

central program of requirements according to the day segmentation. The

day (24 hours) can be divided into up to 8 segments each having required

temperature, humidity and radiation. The control is carried out

(according to the element setup) to maintain the required condition

throughout the day.

On the basis of the above sensors the system operates the greenhouse

components.

Up to 4 greenhouses climate controlled systems can be setup each

containing

Windows

(Curtains) (up to 10 - including roof windows): Each of the windows can

open up in 10 stages according to temperature, humidity, wind, rain,

logic conditions and processes such as CO2 and spraying.

Fans (up to 4)

Refers to the fans installed on the side wall of the greenhouse and

exhaust the air outside the green house letting fresh air into the green

house from the opposite wall. Up to 4 groups of fans can be controlled

per greenhouse. The fans can be programmed to work according to the

conditions mentioned for the windows along with cyclic programs that can

change the cycle automatically according to the temperature. The fans

can be dependent on other process in the same way as the windows.

Thermal Screens (up to 4)

An element in the greenhouse that can be spread or rolled up according

to the level of the radiation and/or the temperature.

Up to 4 opening stages can be setup.

Cooling System (up to 4)

The cooling system is either wet pads or fogging systems. It can be

operated according to the temperature, humidity or other conditions. The

process of cooling includes in many cases operation of other elements

such as fans in the case of cooling pads.

Heating System (up to 4)

The methods of heating the greenhouse are either hot water heating or

air heating. The heating system is normally programmed to maintain a

certain air temperature by starting and stopping the heating output.

When greater accuracy is required or in more severe conditions a special

program of "Circulating Heating" is available, allowing PID control of

the water temperature, according to the air temperature and the heating

conductivity data of the greenhouse. Heating can be dependant on

humidity and other conditions.

CO2 Enrichment (up to 4)

A program controlling the operation of the CO2 valve.

The process of CO2 may include some other elements such as windows, air

circulating etc.

Spraying (up to 4)

This system usually includes a special device that emits pesticide spray

in a certain location in the greenhouse. The process includes closing

windows and operating the air circulating in order to ensure that the

pesticide reaches all points of the greenhouse.

Air Circulating (up to 6)

Refers to fans installed inside the greenhouse that cause air

circulation inside the greenhouse. The programs of these elements

include cyclic operation according to temperature, humidity and

processes such as spraying, CO2 and many others. This same element can

be used also for lighting and others.

Galileo - Alarm Activation

Activated in the case of system failure such as over/under flow rate,

uncontrolled water, missing water

meter pulse and extreme climate conditions.

Alarms can be issued via an external device such a siren or a flashing

light. They can also be sent as an S.M.S text message to a cellular

phone or as an email. |